Transforming Surfaces, Enhancing Durability: Your Powder Coating Experts

About Us

With over five years of steadfast presence in the industry, we’ve honed our craft to perfection, specializing in state-of-the-art powder coating and finishing solutions. Whether it’s automotive parts, furniture, architectural elements, or industrial components, our precision application process ensures a flawless finish every time.

Our journey has been defined by an unwavering commitment to excellence and an unyielding dedication to both quality and customer service. Trusted by renowned brands like Canadian Tire, Ikea, Honda, and many others, we continue to set the standard for superior craftsmanship and unparalleled client satisfaction.

Why Powder Coating

Our Process

01

02

03

04

05

Powder Types

Epoxy

Common uses include automotive parts, appliances, industrial equipment, infrastructure, and architectural components.

Polyester

Common uses include outdoor furniture, equipment, and automotive parts.

Polyurethane

Polyurethane offers a wide range of gloss levels and textures, providing both aesthetic appeal and long-lasting protection in diverse industries.

Hybrid

Hybrid powder coating offers a balance between performance and cost-effectiveness, making it a popular choice for various industries.

Metallic

These coatings are environmentally friendly, as they contain no volatile organic compounds (VOCs) or solvents.

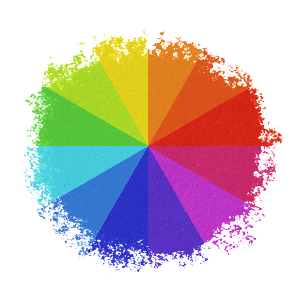

RAL Colors

With RAL colors, standardization ensures consistent color reproduction across materials and industries, simplifying communication and eliminating guesswork.